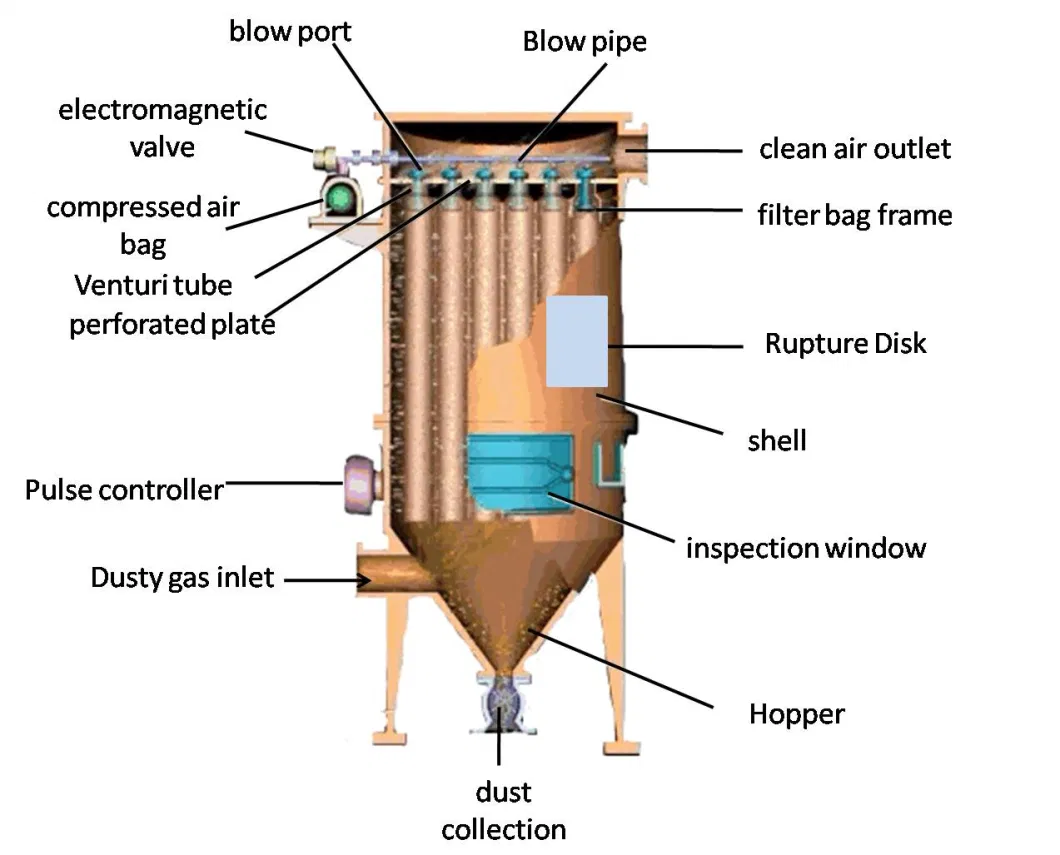

Sistema de filtro de coleta de pó de preço de fábrica, ciclone industrial downdraft/saco/molhado/coletor de pó de água para fumos/soldagem/cimento/carpintaria/pó/triturador

Visão geral Tamanho do pacote 260,00 cm * 200,00 cm * 800,00 cm Peso bruto do pacote 2.000,000 kg Prazo de entrega 15 di

Envie sua consultaDESCRIÇÃO

OverviewInformação básica.

| Modelo NÃO. | SO |

| Material Médio | Fibra Metálica |

| Método de coleta de poeira | Seco |

| Tipo | Coletor de pó de tecido |

| Poder | 5,5 kW - 150 kW |

| Volume de ar | 6000m3/H-150000m3/H |

| Operação Ntipo | Automático |

| Tamanhos | Múltiplo |

| Ao controle | Automático |

| Características | Sistema modular central de remoção de poeira |

| Personalizado | Sim |

| Serviço pós-venda | Serviço on-line |

| Tratamento | Tratamento Biológico |

| Método N de instalação | Vertical |

| garantia | 1 ano |

| Automação | Automático |

| Parafuso | Multiparafuso |

| Doença | Novo |

| Pacote de Transporte | Embalagem padrão |

| Especificação | Altura: 8m, Largura: 2m, Comprimento: 2,6m-11,5 |

| Marca comercial | OYANG ou OEM |

| Origem |

Produtos relacionados

-

![Para rebarbar, irradiar e alisar a superfície das peças com abrasivo de mídia plástica]()

Para rebarbar, irradiar e alisar a superfície das peças com abrasivo de mídia plástica

-

![Polidor de abrasão de ar de alumina dentária sandblaster com função de resfriamento de água 4 furos estilo de acoplamento lixadeira dentária arma polidor de ar dental]()

Polidor de abrasão de ar de alumina dentária sandblaster com função de resfriamento de água 4 furos estilo de acoplamento lixadeira dentária arma polidor de ar dental

-

![O carro do ODM fez à máquina peças sobressalentes de usinagem CNC da máquina de sopro de areia da motocicleta da peça]()

O carro do ODM fez à máquina peças sobressalentes de usinagem CNC da máquina de sopro de areia da motocicleta da peça

-

![Marca Taa]()

Marca Taa